|

|

|

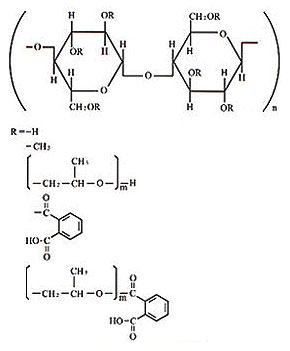

Hypromellose Phthalate Also Known as HPMCP or HydroxyPropyl MethylCellulose Phthalate or

Hypromellose Phthalate Also Known as HPMCP or HydroxyPropyl MethylCellulose Phthalate or

Cellulose, 2-Hydroxypropyl methylether, phthalic acid ester. Chemical CAS 9050-31-1.

Struture :

Specifications:

| Item |

HPP-55 |

HPP-55S |

HPP-50 |

| Dissolving pH |

>= 5.5 |

>= 5.0 |

| Labeled Viscosity (cps) @ 20oC |

40 |

150 |

55 |

| Viscosity (cps) @ 20oC |

32-48 |

136-204 |

44-66 |

| Phthalyl content |

27.0-35.0% |

21.0-27.0% |

| Nominal Phthalyl content |

31% |

31% |

24% |

| Description and solubility |

Conforms |

| Identification (Infrared AAbsorption) |

Conforms |

| Water |

No more than 5.0% |

| Residue on ignition |

No more than 0.20% |

| Chloride |

No more than 0.07% |

| Heavy Metals |

No more than 0.001% |

| Free phatelic acid |

No more than 1.0% |

Physical form :

Powder/Flakes.

Properties :

"HPMCP" (hydroxypropyl methylcellulose phthalate), an enteric coating. It is widely used as an enteric coating agent by the pharmaceutical industry. "HPMCP"

It can dissolve at pH 5-5.5 and be controlled by varying the phthalyl content. Two types of different pH solubility, HP-55 and HP-50, are available. A suitable grade of "HPMCP" for a particular purpose should be selected in accordance with the properties and formulations.Moreover,HP-55S a special type of HP-55 which is distinguished by its higher molecular weight and higher resistance to simulated gastric fluid.

HP-55 is applicable as ageneral enteric coating agent.

HP-55S, because of its high degree of polymerisation compared with HP-55,tends to have higher viscosity solution,higher mechanical strenght of film and higher simulated gastric fluid resistance of the coating formulation.these characteristics are effective in reducing theamount of coating and in preventing crack generation in film applied to fragile tablets or granules.

HP-50 can be dissolved at a lower pH and is therefore applicable to preparation which are designed to disintegrate in upper part of Small Intestine.

It is available in BP/USP/NF/EP.

Applications :

1. Film coating of tablets

2. Enteric coating of tablets

3. Sustained release

4. Delayed release

5. Pallate coating material

Advantages of film coating :

Enhance palatability by masking unpleasant tastes or objectionable odours

Ease ingestion/swallowing

Improve product appearance

Protect tablets from light, oxidation & moisture

Advance the perception of superior product efficacy

|

|

|

|